Wear Protection

Services

- New construction

- Assembly and disassembly

- Technical consulting

- Repair

- Overall implementation

- Emergency handling

- Project support

- Material delivery

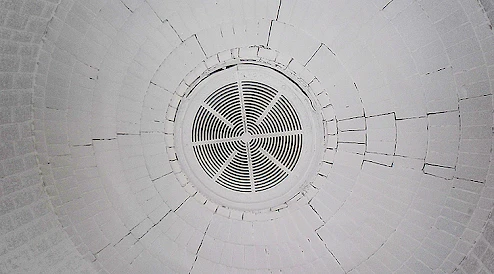

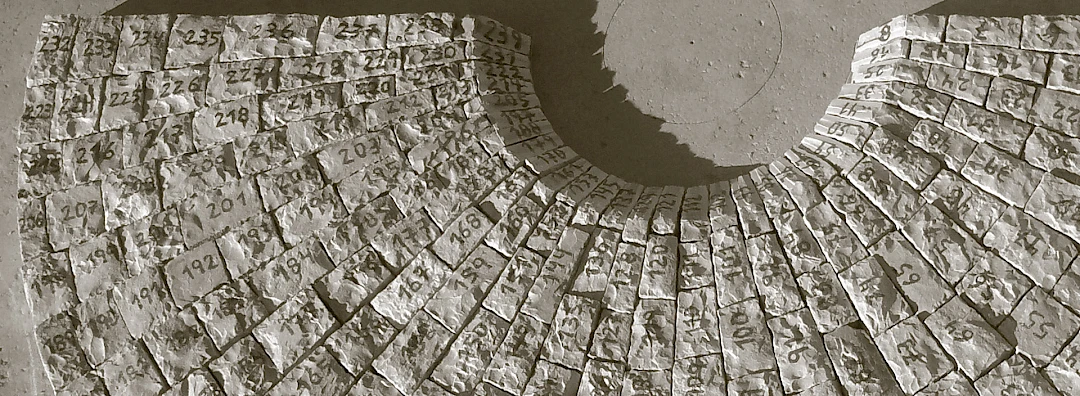

More than 30 years of experience have made us experts in wear protection. Our services include new construction, renovation, repair, or dismantling of all types of industrial mills such as drum and ball mills. We supply high-quality mill linings in aluminium oxide, steatite, silex, and rubber, and the grinding accessories to match, from our own warehouse. This ensures uninterrupted availability of materials, also during the construction phase. Our competent specialists provide technical consulting and support for your project – worldwide if desired. Modern work equipment and occupational safety are matters of course for us. We handle emergencies quickly, efficiently, and anywhere in the world.

Wear protection in reliable professional quality!

Projects

- Ball mills & grinding plants of all kinds

- Mixer

- Classifiers & hoppers

- Pipelines

References

Günter Schulz GmbH & Co. KG – wear protection from the specialist

What seems extreme to others is everyday life for us: dealing with high levels of wear and tear. With more than 25 years of experience in technical wear protection, Günter Schulz GmbH & Co. KG covers almost the entire industrial spectrum. Our work focuses on the raw materials processing and ceramics industries, technical plant engineering and power plant technology. From advice to engineering and material selection through to ready-to-use assembly, maintenance and documentation, we offer our customers all services from a single source. Modules or service packages can be selected from our extensive range to suit your needs. In addition to the project planning and processing of original equipment, we support our customers throughout the entire lifespan of their systems and ensure that existing systems are kept close to the state of the art. Our knowledge from the construction of new buildings is incorporated into the operation of old systems, as are the further developments of materials and assembly technologies.

Our know-how in technical and industrial wear protection and in the area of industrial mills:

• New construction: We offer individually tailored solutions for the new construction of industrial mills and the installation of technical wear protection systems, starting from concept development through to practical implementation.

• Assembly and dismantling: Our services include wear protection linings, the assembly and dismantling of industrial mills, including, for example, ball mills, grinding systems of all kinds, mixers, classifiers, bunkers and also corresponding pipelines.

• Repair: Lining industrial mills is a routine business for us as we have been working in this field for more than 30 years. Repairs are part of our services to ensure the operation of the mills and to restore them quickly.

• Overall implementation: We will be happy to assist you from the preparation of the offer to the final implementation of your project. You can plan your project in detail with an experienced project manager. We provide all-round services to complete your order – it doesn’t matter where the location is. We are flexible and internationally experienced.

• Emergency operations: We know that short-term failures in industrial plants cause immense costs. For this reason, we are available to you at short notice for emergencies. Since we have access to a large material warehouse, material availability is often not a problem.

• Project support: Our project managers are at your side throughout the entire project. They are experienced in industrial wear protection and use their know-how to offer you project-specific support and provide you with flexible support.

• Material delivery: At our location in Saxony-Anhalt we have a warehouse with many refractory and ceramic materials that we can access at short notice. In this way, we avoid delivery problems to construction sites and can react flexibly to emergencies.

We have extensive experience and extensive specialist knowledge in wear protection, particularly in the following areas:

• Supply and dismantling/assembly of wear-resistant linings

• Repairs or repairs of damage caused by accidents

• Shutdown planning and renovation concepts

• Prefabrication of system components including steel construction

• Technical advice on all aspects of the grinding process

• Planning, manufacturing and delivery of pipeline components including wear protection monitoring

• Analysis of wear protection processes

• International assignments

• Wear-resistant linings

Examples of our completed projects in the industrial mill sector include:

• Ball mills

• Mixer

• Vibrating tube mills

• Piping

• Delivery bunker

• Transfer bunker

• Mobile blast furnace bunkers

• Gutters

• Screw conveyors

• Funnel

• Injection devices

• Prototypes

• Test facilities

• Grinding systems of all kinds

• Churning

• Ribbon handovers

Günter Schulz GmbH & Co. KG is your partner for wear protection, wear-resistant equipment and lining and for all upstream and downstream processes. We are happy to support you in national or global projects and support your project with our know-how in the area of technical wear protection.

Industries in which we are currently active:

• Ceramic industry

• Raw material processing industry

• Power plant technology

• Energy production

• Iron / Steel / Aluminum Industry