Top training company 2024

10.02.2025

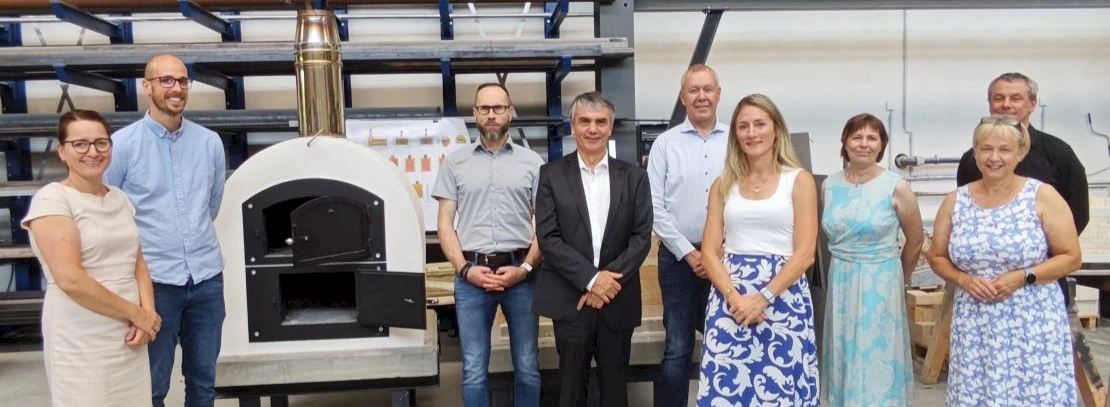

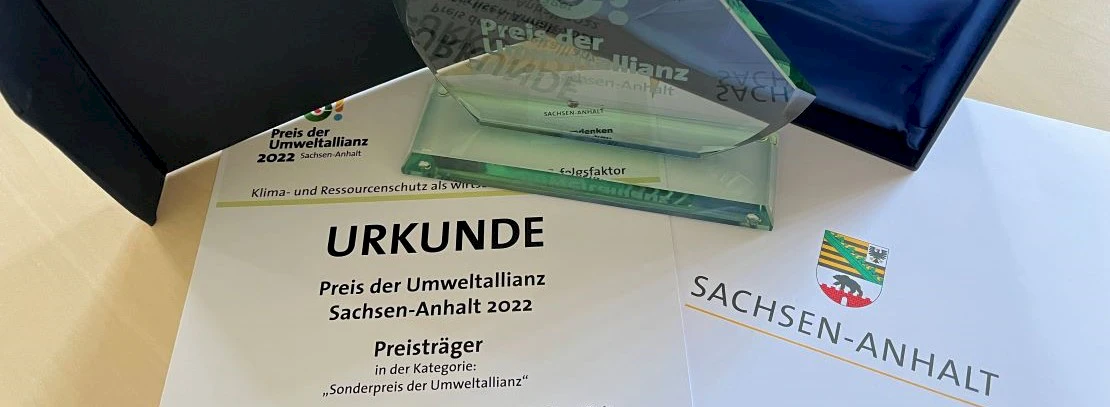

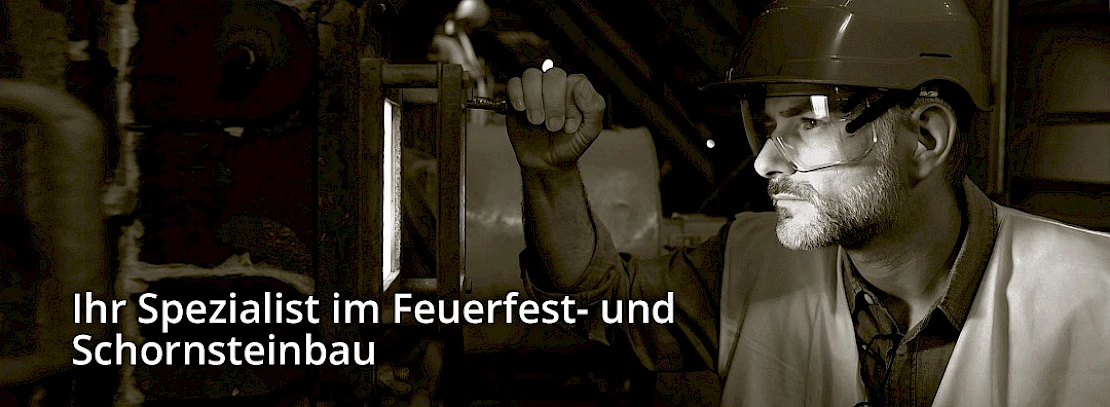

In January 2025, we were once again recognized as a "TOP Training Company" by the Chamber of Crafts of Saxony-Anhalt. After receiving the award in 2022, we were honored again on January 30, 2025, for the year 2024. This recognition confirms our continuous commitment to vocational training in the crafts sector.

Dirk Neumann, Chief Executive Officer of the Chamber of Crafts Halle, said at the award ceremony: "We highlight the achievements of training companies that promote apprentices above average. Sometimes it is the seemingly small things that speak for a company, such as when apprentices are well integrated from day one and feel that they are part of the team."

Criteria for this award include the number of apprentices, their exam results, additional company offers, and the opportunity to acquire additional qualifications. In our company, apprentices participate in numerous training seminars, and migrants receive additional language courses. A special feature of our training is open communication: there are individual conversations between apprentice and trainer that are neither time nor topic-limited and can take place at any time. We also fully reimburse the ticket for public transport and subsidize travel costs. After successfully completing the training, we offer our apprentices permanent employment.

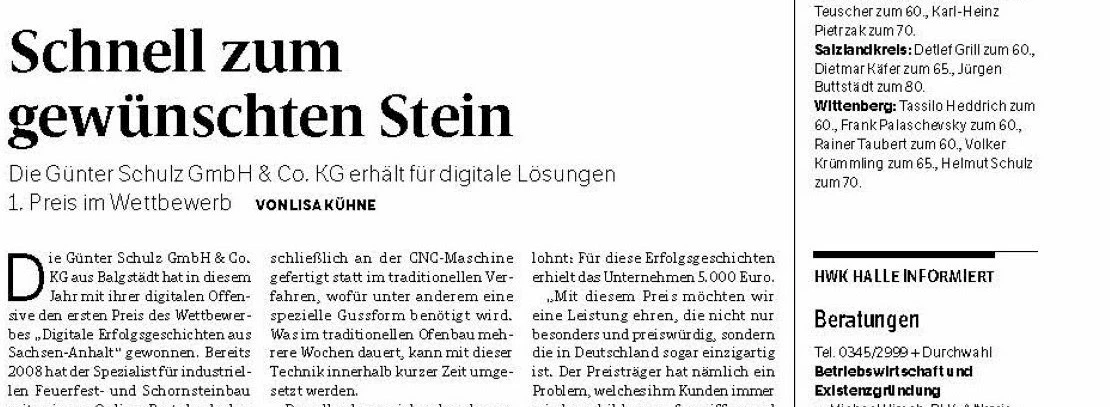

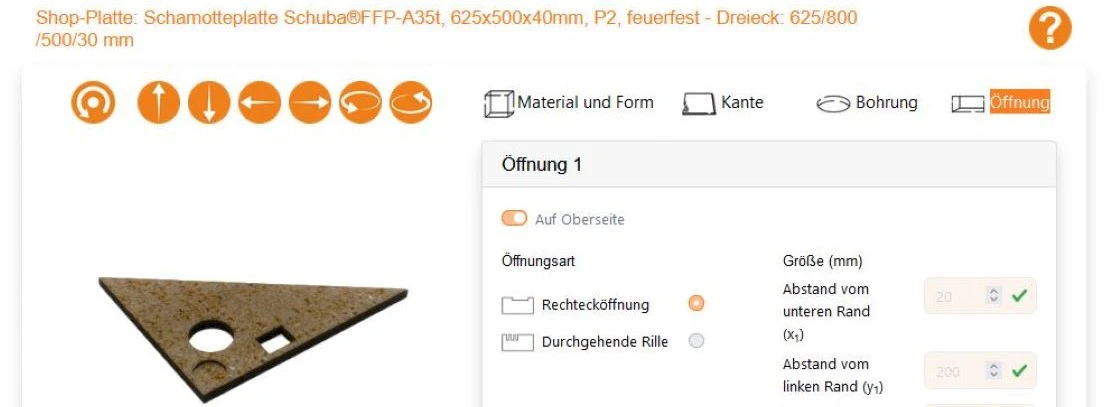

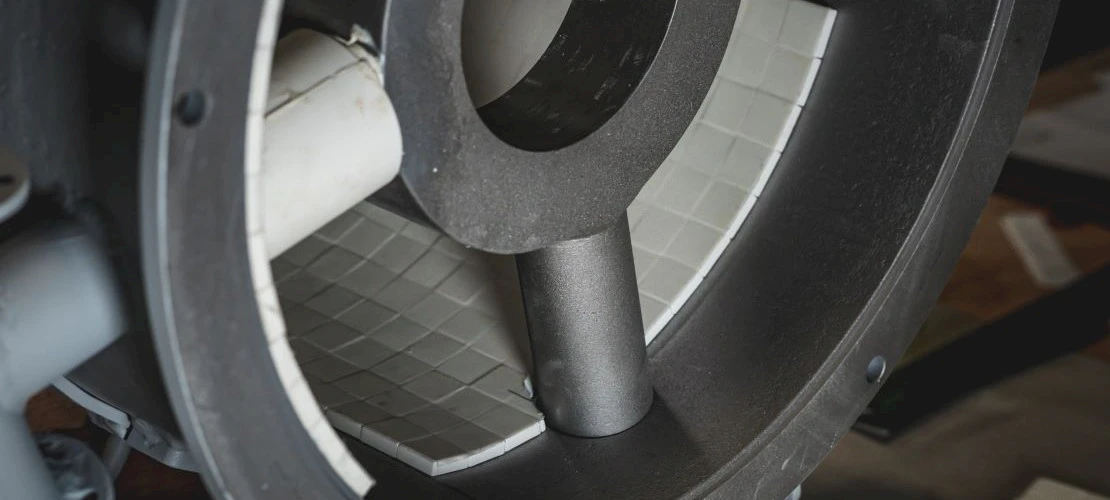

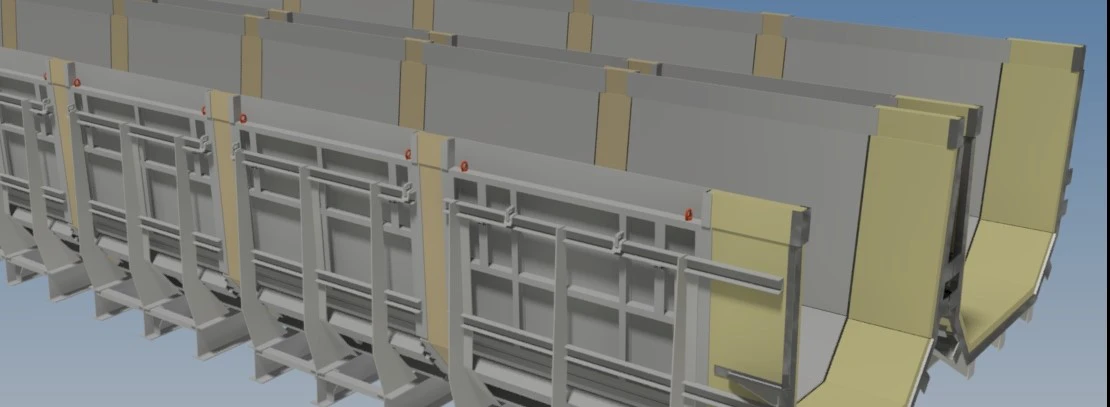

We are proud to be a company operating worldwide in the field of furnace and chimney construction and to have been training qualified young people for over 30 years. Our central training profession is bricklaying. To secure our own skilled labor needs, our apprentices are involved in construction sites and projects from the very beginning - not only in Germany but also internationally.

The renewed award strengthens us in our path to inspire young people for the craft, to shape them, and to adapt the profession of furnace and chimney builder to new conditions. Craftsmanship is tradition, future, and an essential part of our lives.

Links for further reading at the Chamber of Crafts:

https://www.hwkhalle.de/dmh-2024/

https://www.hwkhalle.de/top-ausbildungsbetriebe-2024/

Link to our company video:

https://youtu.be/tk3F4m6iCzQ